Basic tips for diagnosing 4.0L Jeep Cherokee RENIX fuel

injection systems.

What tools do I need to test my fuel injection

system?

Get one of these... . .

I paid under $30 for my fuel pressure guage but you may be

able to borrow one from your local auto parts store's "Tool Rental" program for

free. To properly diagnose your system you must check fuel pressure using a

fuel pressure guage.

Test procedures are intended for RENIX

4.0L engines only. 2.5L engines have THROTTLE BODY

INJECTION and HO engines have a different fuel system!

MPI Fuel System Pressure Test

The MPI fuel system used in vehicles equipped with a

4.OL engine employs a vacuum balanced pressure regulator. Fuel pressure

should be approximately 55-69 kPa (8-10 psi) lower with the vacuum line

attached to the regulator than with the vacuum line disconnected. System fuel

should be 214 kPa (31 psi) with the vacuum line connected to the regulator and

269 kPa (39 psi) with the vacuum line disconnected. CAUTION: Some fuel

may be discharged when connecting fuel gauge to fuel rail.

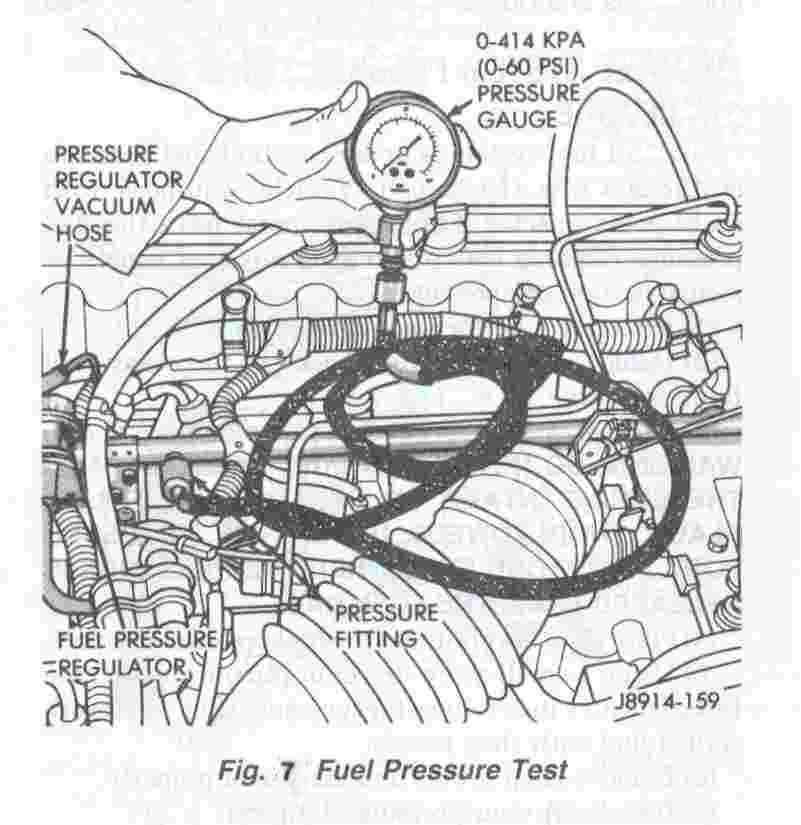

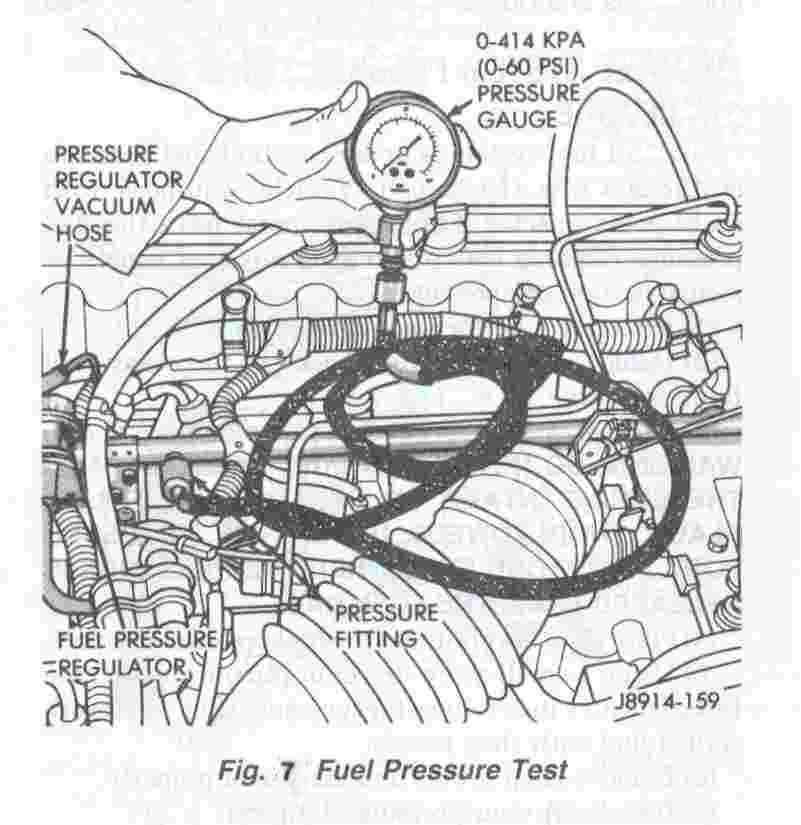

- Connect a 0-414 kPa (0-60 psi) fuel pressure

gauge to test port pressure fitting on fuel rail (Fig. 7).

- Remove vacuum line from pressure regulator.

- Start the vehicle.

- Note gauge reading. With vacuum line

disconnected, fuel pressure should be approximately 269 kPa (39 psi).

- Connect vacuum line to pressure regulator. Note

gauge reading. Fuel pressure should be approximately 214 kPa (31 psi).

- If fuel pressure is not approximately 55-69 kPa

(8-10 psi) higher with vacuum line removed from regulator, inspect pressure

regulator vacuum line for leaks, kinks or blockage. CAUTION: Fuel pressure will

rise to as much as 655 kPa (95 psi) when the fuel return tine is pinched shut,

shut engine down immediately after pinching oft fuel return line.

- If fuel pressure is low, momentarily pinch shut

the hose section of the fuel return line. If fuel pressure remains low, inspect

the fuel supply line, fuel filter, and fuel rail inlet for blockage. If fuel

pressure rises replace fuel pressure regulator.

- If fuel pressure is above specifications, inspect

the fuel return line for kinks and blockage.

Capacity Test

- Remove the cap from the pressure test port in the

fuel rail.

- Connect a 0-414 kPa (0-60 psi) fuel pressure

gauge to the pressure fitting on the fuel rail (Fig. 7).

- Start the vehicle. Pressure should be approxi-

mately 214 kPa (31 psi) with the vacuum hose connected to the pressure

regulator and 269 kPa (39 psi) with the vacuum hose removed from the pressure

regulator.

- If the pressure is not to specification, check

the following before replacing the fuel pressure regulator:

- 4a - Inspect the fuel supply and

return lines/hoses for kinks or restricting bends

- 4b - Check the fuel pump flow

rate. A good fuel pump will deliver at least 1 liter of fuel per minute with

the fuel return line pinched off. If the fuel pump does not pump adequately,

then inspect the fuel system for a plugged fuel filter or fuel pump inlet

filter (sock). Fuel pump flow rate can be done by connecting one end of an old

A/C gauge hose to the fuel test port on the fuel rail and inserting the other

end of the hose into a container of at least 1 liter capacity. Run the fuel

pump by installing a jumper wire into diagnostic connector terminals D1-5 and

D1-6. Be sure to pinch off the fuel return line or most of the fuel will be

returned to the fuel tank.

The RENIX 4.0L fuel pressure regulator is not

adjustable.

MPI Fuel Pressure Leak Down Test with Engine

Off

If abnormally long periods of cranking are

required to restart a hot engine after the vehicle has been shut down

for a short period of time, fuel pressure may be bleeding past the fuel

pressure regulator or the check valve in the outlet end of the fuel pump.

- With the engine off, connect an accurate 0-689

kPa (0-100 psi) fuel gauge to the pressure test port fitting on the fuel rail.

- Start the vehicle and let engine idle. Check

fuel pressure reading on gauge. Fuel pressure should be within specifications.

Refer to MPI System Fuel Pressure Test.

- Shut engine off. Note fuel pressure reading on

gauge. Leave fuel pressure gauge connected. Allow engine to set for 30 minutes

and then compare fuel pressure reading on gauge to reading taken when engine

was shut down. A pressure drop up to 138 kPa (20 psi) to a range of 131-269 kPa

(19-39 psi) is within specifications.

- If fuel pressure drop is within specifications,

the fuel pump outlet check valve and the fuel pressure regulator are both

operating normally.

- If fuel pressure drop is greater than 138 kPa

(20 psi), restart the vehicle and let engine idle. CAUTION: Fuel pressure will

rise to as much as 95 psi when the fuel return line is pinched shut, shut

engine down immediately after pinching off fuel return line.

- Momentarily pinch shut the hose section of the

fuel return line and shut engine off. Note pressure reading on gauge. Allow

engine to set for 30 minutes. Compare fuel pressure reading to reading taken

when engine was shut down. If fuel pressure drops approximately 138 kPa (20

psi), replace the fuel pressure regulator. If fuel pressure has dropped

considerably more than 138 kPa (20 psi) fuel pressure is bleeding off past the

outlet check valve in pump and the fuel pump must be replaced.

|

If you click on the image, another window will open with

the full page scan of the RENIX fuel injection system pressure test that you

can read online or save to your computer.

Click the image (or here) to view complete diagnostic

diagram WITH DIAGNOSTICS TEXT. Opens in a new window for easy viewing to read,

save or print out. (560kb).

- Make your

own fuel pressure guage!Yep - almost as expensive as buying your own

pressure guage but you might have everything in your toolbox already. Opens in

a new window.

- Change the fuel filter. Mounted just in front of the

fuel tank. Easy to change and you just might be the first person to change

it.

- Check for leaks around injectors... CHANGE YOUR

INJECTOR O-RINGS IF YOU SEE ANY GAS! Do NOT drive it thinking you'll

"be ok" until you can fix it... There have been more than one XJ'r on the

forums who've found out the hard way that a leaking injector WILL torch their

truck. And without marshmallows and hotdogs that just ain't any

fun.

- Look inside throttle body for grime & deposits.

Remove O2 sensor and then clean throttle body and idle stepper

motor with carb cleaner. Clean motor's top end with SeaFoam cleaner. (Great

stuff but makes a smoke cloud you can see for MILES!) Reinstall O2 sensor AFTER

cleaning.

- A clogged catalytic converter can cause severe engine

bog under attempted accelleration and is usually preceded by a rich engine

condition... so maybe those 50# injectors were a little too much, eh?

- FIX the cause of any rich running condition before

adjusting / modifying your sensors!!!

RENIX

Fuel Injection Technical Manual - 100 page / 1.5MB file. - Goes way beyond

the basics.

RENIX

Fuel Injection Technical Manual - 100 page / 1.5MB file. - Goes way beyond

the basics. |

If you have pics of your own repairs or can

suggest other methods - please contribute your ideas (and pictures) to this

article!

|

|

Revised on:

January 25, 2007

|

.

.