Sooner or later it's gonna happen to ya... You'll go outside and

see a big ol' puddle of oil in the driveway under your XJ. With the Jeep 4.0L

it's usually one of three things: the rear main seal, a leaky valve cover

gasket or bad oil filter mount seals. Since you're looking at this page we're

going to assume you've checked your valve cover gasket and your rear main isn't

the problem. (Yeah.... right....) (Ok - we'll assume your rear main seal isn't

leaking THIS bad.)

After ya check the rear main & valve cover gaskets and

you find gobs of oil on the side of the engine around the oil filter... it's

not time to panic. This is a no-brainer and won't set you back but a few

dollars. For a few bucks and maybe an extra hour (or less) added to your oil

change you can fix this easily. The problem is the oil-filter mount o-rings are

well known for getting brittle with age & heat so if your Jeep has a few

miles on it they will eventually give up the ghost and leaks develop around the

oil filter mount.

Let's Get Started!

Note! There are a couple of different o-ring styles.

|

HO engines have an o-ring 'kit' available w/ all three

o-rings packaged together so in this regard... you're in luck! Just go to the

dealer and ask for the "kit" with the o-rings together and you'll be ready to

go. Getting the o-rings isn't much easier than that! The hard part will come

when you start cussing that TORX bolt holding the filter mount on.

|

|||||||||

|

Early / RENIX engines require that you buy all three o-rings seperately as they do NOT interchange with the HO o-rings. This is due to the different center bolt (TORX vs. hex head) that retains the filter mount. No big deal - they're a stock item for the dealer. These o-rings may be available at your local auto-parts store as well - they aren't anything special but you must have the correct sizes to prevent more leakage! Here are the dealer part numbers and sizes for the RENIX o-rings:

|

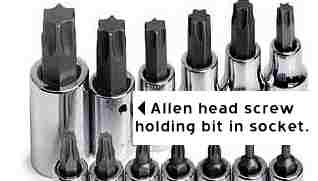

This

is a early 4.0L mount which you can remove with a box end wrench.

Be

aware that newer models usually have a T-60 TORX head fitting that is more

difficult to access. SOME of you may also find allen head bolts here.

A

note on tools here: Newer XJ's with the Torx & allen-head style bolt are a

bit of a pain to remove but not bad with the correct tools.

Don't try to fudge on tools here... you NEED the correct size torx socket if

your bolt has a torx head!

S & K Tools (and others) make a T60

sockets with the Torx bit held inside by an allen screw that you can loosen to

remove the bit.

The cheapest ( and nearly useless ) versions will be one

piece... (DON'T get the one piece socket-bits!).

The next step up

will have the bit -pressed in-. If you get the ones that are pressed in, you'll

have to pound them out with a flat punch & a hammer as they aren't really

intended to be separated. You may end up ruining the socket but it's the bit

you're really after here.

Best is the high-grade ones where you can loosen

an allen screw and remove the bit anytime. Either way, once you have the bit

out, you just use the hex part with it's torx end inside of a box-end wrench

(10MM???) which gives you enough room to work where the socket-bit won't fit

with a ratchet.

|

|

|

SOME XJ's may have 9 / 16" allen socket head bolts. You'll need to find an allen bit socket for these but be sure to get one where the bit is removable. You can also cut down a standard allen wrench to about 1 1/2" in length. (Short enough to leave in bolt head and still remove bolt and filter mount.) You'll insert either the bit, or the cut off allen-wrench into a box end wrench and use it to remove the bolt. |

Update: Posted by tsc on J.U. - "I have a 92 ZJ

4.0 that was a very large allen wrench.... Not all of them were

Torx."

Yay. Yet another variation of the Three-Stooges

mentality down at Daimler-Chrysler to warm our hearts while lying on our back

in a mud-puddle on a 33* day trying to figure out why the tool that fixed one

XJ won't fix another...

Be aware that engine swaps from ZJ's etc are

common and you might end up with an allen bolt here... and that some XJ's

appear to have had the allen bolt as well.

Disassembled

mount showing old seals that were so brittle they had snapped in two upon

removal.

Cleaned

up the mount & repainted it. New o-rings shown on left.

Smallest

o-ring goes here.

Middle

sized o-ring goes here.

Bolt

with smallest o-ring fits inside mount with medium o-ring like this. I used a

small amount of oil just to slip them together.

Largest

o-ring goes here. Hold it in place with some axle grease inside the o-ring's

seat. Make sure it stays seated while you replace the mount and doesn't get

pinched. Do NOT overtighten the mount's bolt specs for your type bolt.

Again: Get the correct o-rings for your mount! If your filter mount uses the Torx style bolt you will need the 'kit'; if you use a box-wrench to remove the center bolt you'll have to get the o-rings seperately and they MUST be the correct size!

If you have pics of your own repairs or can suggest other methods - please contribute your ideas (and pictures) to this article!

|

|

|

Revised on:

March 6th, 2007 |