This page contains information courtesy of Eric Giordano (JabaThaHut).

This page contains an easy to follow set of diagnostics for your early model 4.0L Jeep Cherokee with RENIX based (NON-HO / early)engines & sensors.

This information was provided by JabaThaHut and was also posted on Jeeps Unlimited. This information is provided with his permission and has been edited to add my own photos and additional information. I urge you to THANK ERIC if this information helps ya as it was his effort that got this information collected and this page would not exist without it! Other tidbits are added as they happen but the bulk of this page is Eric's work.

(Eric's information begins here: )

"Here's something I wrote up a while ago for someone describing tests for the sensors. I had done all these in hopes to find and eliminate the poor running I was experiencing. If you need anything to be clarified, let me know.....

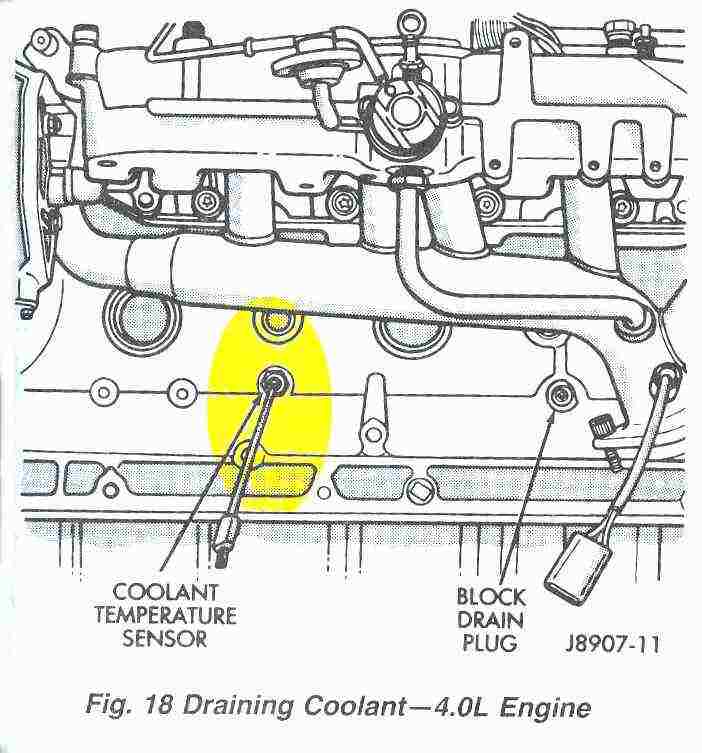

Coolant Temperature Sensor (CTS)

Located in engine

coolant jacket on the driver's side of the block. To test, use a high impedance

volt-ohmmeter. Resistance should be less than 1000 ohms with a WARM engine

(examples = 212* would be about 185 ohms, 160* would be about 450 ohms, 100*

(not warm enough) would be 1,600 ohms).

> What does it do? Adjusts

the injector pulse widths (Colder coolant temperatures result in longer

injector pulse widths and richer air-fuel mixtures). Compensates for fuel

condensation in intake manifold. Controls engine warm-up idle speed. Increases

ignition advance when engine is cold. Energizes the EGR valve solenoid to

prevent flow of vacuum to the EGR valve.

Update:

Basically - this sensor functions by providing a resistance-to-ground circuit

that the computer (ECU) uses to determine how much fuel the engine requires.

(The hotter the coolant - the lower the resistance.) The resistance of the

sensor is read by the ECU which in turn adjusts the air/fuel ratio as close to

14.7:1 as possible. When a coolant temperature sensor fails (open circuit / no

continuity) the high / infinite resisitance will cause the ECU to falsely read

the max low temperature of -40 degrees F. The ECU then tells the injectors to

enrichen the fuel mixture because it thinks the temp is really cold when it

really isn't. A short to ground would cause a 'no-resistance' fault causing the

ECU to think the coolant air temperature was extremely hot and lean out the

fuel mix.

Unlike late HO engines; RENIX engines do NOT have a

combination coolant temperature sensor that also feeds the gauge! RENIX

vehicles use a SEPARATE sensor located on the back half of the head, driver

side (See bottom of page.)

Resistance chart for both Coolant Temperature

Sensor

-and-

Manifold Air Temperature

| Coolant

Temperature and Manifold Air Temperature Sensor Resistance

Values Approximate resistance your meter should show at the temperature shown in the chart. NO resistance indicates a 'short' to ground - can be the sensor but will usually be a wire where the insulation has been abraded. INFINITE resistance indicates an 'open / broken circuit. Can either be a broken wire or a bad sensor. |

||

| Degrees Fahrenheit | Degrees Celcius | Resistance in Ohms |

| -40 | -40 | 100,700 |

| 0 | -18 | 25,000 |

| 20 | -7 | 13,500 |

| 40 | 4 | 7,500 |

| 70 | 20 | 3,400 |

| 100 | 38 | 1,600 |

| 160 | 70 | 450 |

| 212 | 100 | 185 |

Manifold Air Temperature Sensor (MAT)

OEM location of MAT sensor is at end of tape measure. |

Relocated MAT sensor shown on Rusty's air tube. |

Installed in the top of the intake manifold. Testing is the same

as the CTS. Make sure engine is WARM.

> What does it do? Pretty much

the same thing as the CTS, but based off incoming air temperature.

Update: Basically - this sensor functions by providing a resistance-to-ground circuit that the computer (ECU) uses to determine how much fuel the engine requires. (The hotter the air in the intake manifold - the lower the resistance.) The resistance of this sensor is read by the ECU which in turn adjusts the air/fuel ratio as close to 14.7:1 as possible. When a manifold air temperature sensor fails (open circuit / no continuity) the high / infinite resisitance will cause the ECU to enrichen the fuel mixture because it thinks the temp is really cold when it really isn't. A short to ground would cause a 'no-resistance' fault causing the ECU to think the air temperature was extremely hot and lean out the fuel mix.

Manifold Absolute Pressure Sensor (MAP)

MAP sensor.  Located on driver side of firewall just behind & above engine. |

Located on firewall behind valve cover. To test, using a

voltmeter with the ignition on/engine off, voltage at terminal B should be 4 -

5 volts. The voltage should drop to 1.5 - 2.1 volts with a HOT, neutral idle

engine. Supply voltage can be checked at terminal C with the ignition on.

Voltage there should be 5 volts + or - 0.5 volts (Terminal A is the ground

wire).

> What does it do? Compares ambient barometric pressure

during start-up (cranking) to engine load while engine is running. The ECU

computes that information and adjusts the air-fuel mixture accordingly.

Here's a video of a YJ owner testing his MAP sensor.

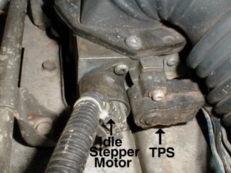

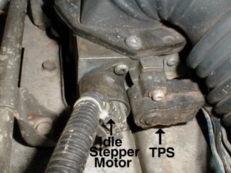

Throttle Position Sensor (TPS)

TPS and Idle Stepper Motor. Located on throttle body facing toward radiator. |

Located on the right side of the front of the throttle body. To

test, disconnect the connector at the TPS. Check the voltage at TPS connector

pins B (Ground) and A (5.0 volt supply) with the ignition on. If you see about

5 volts, hook up the connector again. and check the voltage at TPS terminals C

(positive) and B (Ground) with the ignition on and the throttle plate closed.

You should notice approximately 0.8 volts. If you see that voltage, your TPS

and wiring should be ok. If not, you'll have to adjust the TPS to get that

voltage. If you cannot adjust the TPS to get that voltage, you'll have to

replace the TPS and adjust the new one properly. Also, with the voltmeter

hooked (terminal C) up and the ignition on, move the TPS arm down and back up

slowly and watch the voltage. The change should be increasing and smooth. If

there are any dead spots or it is not smooth, it probably needs to be

replaced.

> What does it do? The voltage is interpreted by the ECU to

determine current engine operating conditions. Just as a note to you, the

automatic transmission versions have 2 integral connectors (1 for ECU and 1 for

tranny). If you have the auto, make sure you're checking the right connector

(I'm not exactly sure what it looks like as I have the manual tranny).

Update: Suggestion: If you are having intermittant idle / surge issues and can't quite get the voltages to set right - before going out to buy a new TPS try checking your ground connection. Renix engines are notorious for having bad / faulty ground connections as a result of age and not so great design in the connectors. A common "fix" is to add a jumper ground wire from the TPS ground that bypasses the connector and harness entirely.

|

Idle Speed Stepper Motor - (aka Idle Air Controller / I.A.C.)

|

Located on the left side of the front of the throttle body.

Testing requires the use of an "Ele. CT.01 exerciser tool". I don't have one

and don't know exactly what it does, but from what I've heard, it sounds like

it can actuate the motor to advance and retract the pintle. I'm not sure how

much that equipment costs, but I decided to just replace mine. I knew it was

operating, but wasn't sure if it was sticking at all, and it did have a slight

groove in it (the pintle) from use. I figured, the part is 12 years old and has

160,000 miles on it, it could probably use replacing. I had AutoZone order one

for me (I think it was about $65.00... I think they're about $125 from the

dealer). If you get one there, tell them you need the Idle Air Control Valve

for your vehicle or else they won't be able to find it in their database. The

new one I got works great.

> What does it do? The ECU uses it's

information and commands the unit to extend or retract the pintle, which

controls the amount of air which bypasses the throttle plate to maintain idle

speeds.

Here a 1991 YJ owner removes, cleans & replaces his Idle Air Controller. Note that it is different than the RENIX part but same location, same function and similar in appearance.

FOR HO THROTTLE BODIES ONLY!!! - Holley part #543-105 is an idle air control motor for Holley's pro-injection system and will swap for this part for around $28 at AutoZone vs. $125+ at the dealership! |

Oxygen Sensor

Located in the exhaust manifold. To test, using an ohmmeter,

disconnect the O2 sensor connector. Connect the ohmmeter test leads to

connector terminals A and B of the sensor connector. Resistance should be

between 5 and 7 ohms. Replace the sensor is the ohmmeter displays and infinite

reading. I don't know about you, but this test is pretty vague. They say it

should be between 5 and 7 ohms, but infinite is bad. What if you get a reading

of 13 ohms or 100 for that matter? I wasn't too fond of this test as I found it

is a test of the O2 sensor heating element!. One other thing you can do with

the O2 sensor is hook up the voltmeter to terminals B and C (I can't remember

if those are the right letters, but you want to get the sensor wire (believe it

was blue) and the ground wire, or just ground to something else) with the

connector hooked up and the engine on, warm, and idling. You should notice the

voltage jumping up and down in about 2 second or less intervals. If it doesn't

jump up and down considerably or takes longer than 2 seconds to do so, change

it.

> What does it do? The ECU interprets the voltage from this

sensor which analyzes the oxygen content on the exhaust gas and varies the

air-fuel ratio accordingly.

EGR Solenoid

EGR Solenoid. NOTE! This is NOT the EGR valve! Where applicable (RENIX systems) the EGR valve is located on intake manifold. The white object to the valve's right, held in place w/ a single screw in it's center 'nub' with the two orange wires going into it is the ceramic fuel pump ballast resistor. The ballast resistor is a source of intermittant stalling / hard start issues as well. Cheap to replace... easy to break. |

Located on the driver's side fender toward the front of the

vehicle. It has a vacuum line going to and from it as well as an electrical

connector. To test, using a vacuum tester, first verify that vacuum is present

at the vacuum source connector (the one near the electrical connector). I think

it should be around 15 mm Hg at idle. If vacuum is present, remove the output

side connector (two port style) which goes to the EGR valve transducer (looks

like a small black UFO...hehe) Connect a vacuum gauge to output B (the one

closer to the unit... it's a little longer than the other output). Start and

idle the engine. There should be NO Vacuum present at that point. Disconnect

the connector from the solenoid. There should now be vacuum present at output

B. Hook up the connector again and rev the engine a few times. You should

notice vacuum when revving it. The engine must be HOT for this test.

> What does it do? The solenoid allows or denies the presence of vacuum to

it's output, which opens and closes the EGR valve.

EGR Valve

Located on the drivers side of the engine toward the rear. To

test, with engine running, take a screwdriver and open the valve (pull the rod

away from the engine). The engine RPM's should drop and engine should sound

like it's running like garbage (may even stall out). Release the valve and it

should return to normal. If not, it's getting stuck. Mine passed these tests,

but I guess it wasn't closing all the way and you really can't tell if it is or

not. I even took mine off and cleaned it/checked for operation while off the

vehicle. I had to replace mine. As far as the transducer goes, you can open

that up with a screwdriver (the plastic pieces are just snapped together). Like

I said, the rubber diaphragm was real beat in mine and the spring was pretty

much non existent as it was rusted to nothing. I'm not sure what affect the

transducer has on the system, but it comes with the new valve. Remember to get

a new EGR Valve gasket if you replace yours.

> What does it do?

Opens during certain conditions to allow exhaust gasses to run through the

combustion chamber to burn again and reduce emissions."

The above text was provided courtesy of Eric Giordano (JabaThaHut) on J.U. Please be sure to thank him for this easy to follow information!

More %#$$&)(* sensors!

After looking through the above list, I noticed that somehow the Knock Sensor, CAMshaft Position Sensor & the nefarious CRANKshaft Position sensor was left out! (*doh!*)

Here is a video showing some of the sensors.

Knock Sensor

Mounted on lower, driver side of engine block, this small piezo-electrical device tells the ECM to retard ignition timing when it detects engine 'ping' / knock. Often gets damaged when installing engines but looks ok externally. If damaged, it can tell computer to retard ignition intermittantly, under the wrong conditions or not at all and cause anything from rough running to allowing terminal pinging to go unchecked.

OEM knock sensor from my 1990 XJ. |

Connector plug view. Connection is identical to those on a fuel injector. |

Generic replacements. NAPA 1990 XJ replacement - #DKS111 (Echlin) |

Style that supercedes mine. Functionally identical to old unit & plugs right in. |

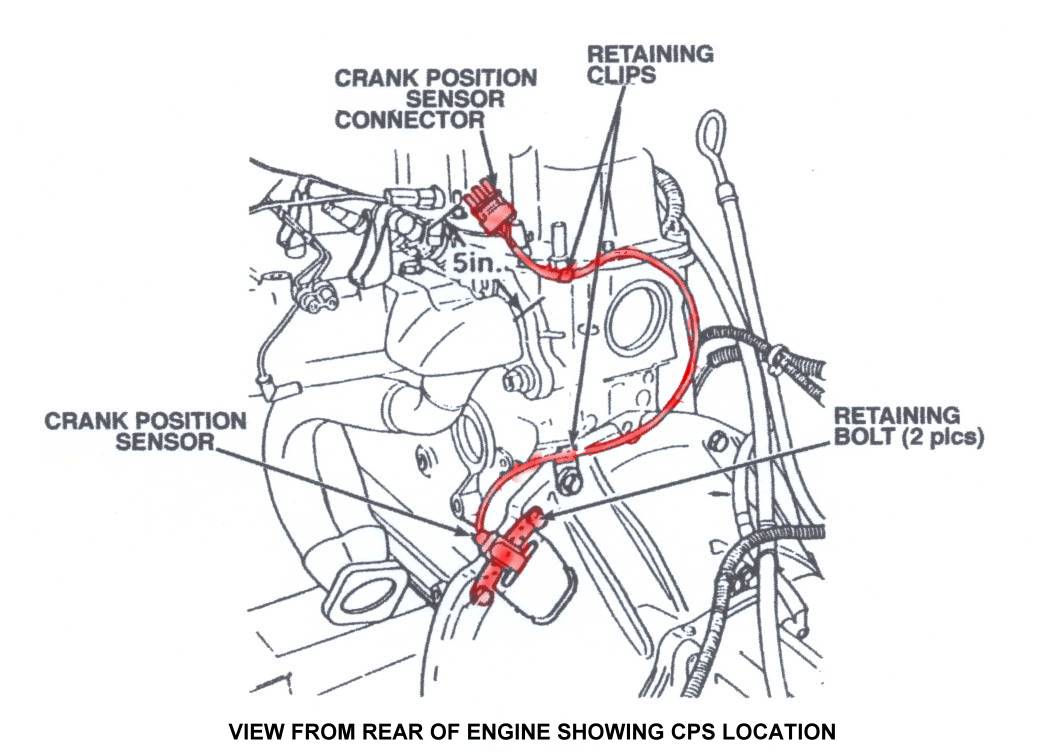

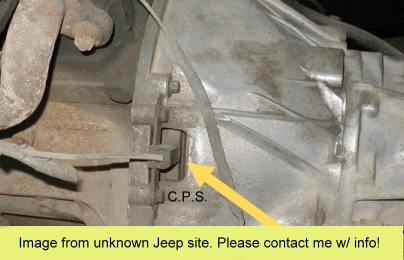

C.P.S. (Crankshaft Position Sensor)

(AKA: CKP and / or engine 'Speed Sensor' in some

Daimler-Chrysler publications.)

Do Not Confuse this with the CAM Position

Sensor located in the "distributor"! Make sure your counterdrone knows which

one you are talking about!

See THIS

LINK for Cam Position Sensor Information.

This is the BIG Kahuna of problems for people with no start, hard to start & stall out issues! You do NOT want to have this fail far from home, wheelin' alone, tools in the garage and no spare anyhow... heck, even if ya did have the tools, helpers and a spare it's a major pain to fix beside the trail! This thing is kinda like a serpentine belt; ya won't remember to replace it until it breaks! Unlike a serpentine belt, SOMETIMES.... just sometimes, ya can limp on home... maybe. The CPS should be a regular maintanence item for any Jeep owner but the change out interval is more likely related to heat & vibration rather than miles. If anyone knows the actual time interval recommended by the factory on these, please let me know and I'll amend this page.

View of uninstalled Crankshaft Position Sensor. |

View of rear of engine showing Crankshaft Position Sensor & harness highlighted in red. |

Great photo showing location of CPS on bellhousing. NOTE: I found this pic on my harddrive and have no clue where it came from. Had cyrillic writing on larger image & probably came from another Jeep site. I do NOT claim credit for this! Please contact for credit or removal. |

Here are a couple of videos to help you with that CPS / CKP test & replacement procedures.

CPS: You can check it's basic function but be aware that sometimes the darn things can be 'intermittant' but still read 'ok' when measured due to engine heat/temperature. Even so, these tests will show up a borderline CPS more often than not.

Check the connector first

If you've just

stalled out with same symptoms... unplug the CPS & plug it back in. If your

motor fires back up you might get off easy, but don't count on it lasting

forever. I dunno what doing this accomplishes other than cleaning the

connector contacts enough to let additional voltage through to the

computer. If unplugging & replugging worked then unplug the connector

again and clean those contacts off. Then apply some OX-GARD, or other

electrical contact cleaner & protectant (dielectric grease).

There

is a distinct possibility that you're not getting a signal due to a faulty

connector itself as well. Some people have cured their CPS problems by simply

cutting the connector out of the harness and SOLDERING the wires together (Use

heat shrink or electrical tape around the wire, of course!) Other's have

replaced the connector with a newer, waterproof version from an electrical or

automotive supply store.

Test#1 - Get a volt/ohm meter and set it to read 0 - 500 ohms. Unplug the cps and measure across the CPS connector's A & B leads. Your meter should show a CPS resistance of between 125 - 275 ohms. If it's out of that range by much; replace it. (* - Note: HO engines are measured from the B & C connectors and should have near zero ohms.)

Test#2 - You'll need a friend to help ya with

this one.

Set your volt/ohm meter to read 0 - 5 AC volts or the closest AC

Volts scale your meter has to this range. Measure across the CPS leads for

voltage generated as your friend cranks the engine. (The engine can't fire up

without the CPS connected but watch for moving parts just the same!) The meter

should show .5 - .8 VAC when cranking. (That's between 1/2 and 1 volt AC.) If

it's below .5vac, replace it.

Desperate last ditch tip to get home or a few more miles from a failing CPS: - Other than the unplug/replug trick... MJR passed on a trick of using a flat bar and a hammer to 'adjust' the CPS by smacking the CPS bracket and forcing a weak CPS just a tad closer to the flywheel. This lets a weak CPS get a stronger pulse and hopefully generate enough voltage to feed a good signal to the computer again. WARNING! - If ya smack it too hard... it'll go in too far and the flywheel will eat the CPS! Start walking.

Either way, if it fails ANY of the tests... you should replace it and save your self some major pain later. If not, at least carry a spare CPS but be aware that it's a royal pain in the ass to change on a cold motor and ya really don't wanna do it at night, on the trail and with a hot motor if ya can help it!

UPDATE:CPS SENSOR

HARNESS REPLACMENT TECHNICAL BULLITEN IN PDF FORMAT.

This one is a

'last resort' fix if you've replaced the CPS already & it didn't fix the

problem. The issue is a crappy harness which this bulliten addresses through a

replacement of the actual CPS harness. (They call it a CKP harness for some

idiotic Daimler-Chrysler reason...)

Tech Tip: - To more easily remove & replace the CPS use a floor jack to support your transmission cross member, remove the two bolts & two studs (replace those with bolts if you break one), then lower the transmission cross member by about 1-2 inches. This will give you enough room to get your hands & tools in for the CPS work. (Especially if you have big hands!)

"Almost" Sensors...

RENIX Coolant Temperature GAUGE Sending

Unit Located at rear of head on driver's side. |

NOTE!: This is NOT the

Coolant Temperature Sensor used by the ECU for engine management!

This is

the temperature sending unit for the temperature guage or idiot light. It is

often removed to 'burp' air from the engine coolant. Late HO engines use a

'combination' sensor in the same location as the RENIX Coolant Temperature

Sensor in the block. (See first diagram at top of page.)

If you are still having problems and need 'word for word' advice then you really should get yourself a Factory Service Manual. MUCH better than a crappy Haynes or Chiltons manual! Just follow the link from the Downloads Page.

I'd also like to put a plug in for Cruiser54's great website! If you have a RENIX Jeep then visit CRUISER54's website! It is a phenomenal resource for RENIX owners.- Off-site link.

If you have pics of your own repairs or can suggest other methods - please contribute your ideas (and pictures) to this article!

|

|

|

Revised on:

December 27th, 2015 |